Hazardous Area

Control Panels

Our technical team is ready to design and build hazardous area control panels tailored to your specific requirements.

Hazardous Area Control Panel Services

As your trusted experts, we specialise in the design and manufacture of hazardous area control panels.

Choosing our services for hazardous area panel design means benefiting from our extensive expertise and commitment to excellence. Our technical team has a deep understanding of ATEX and IECEx standards, ensuring that every panel we design is compliant and safe for use in Zones 1 and 2. We offer bespoke solutions tailored to your specific requirements, utilizing state-of-the-art technology and high-quality materials. Our rigorous testing and quality assurance processes guarantee reliability and durability.

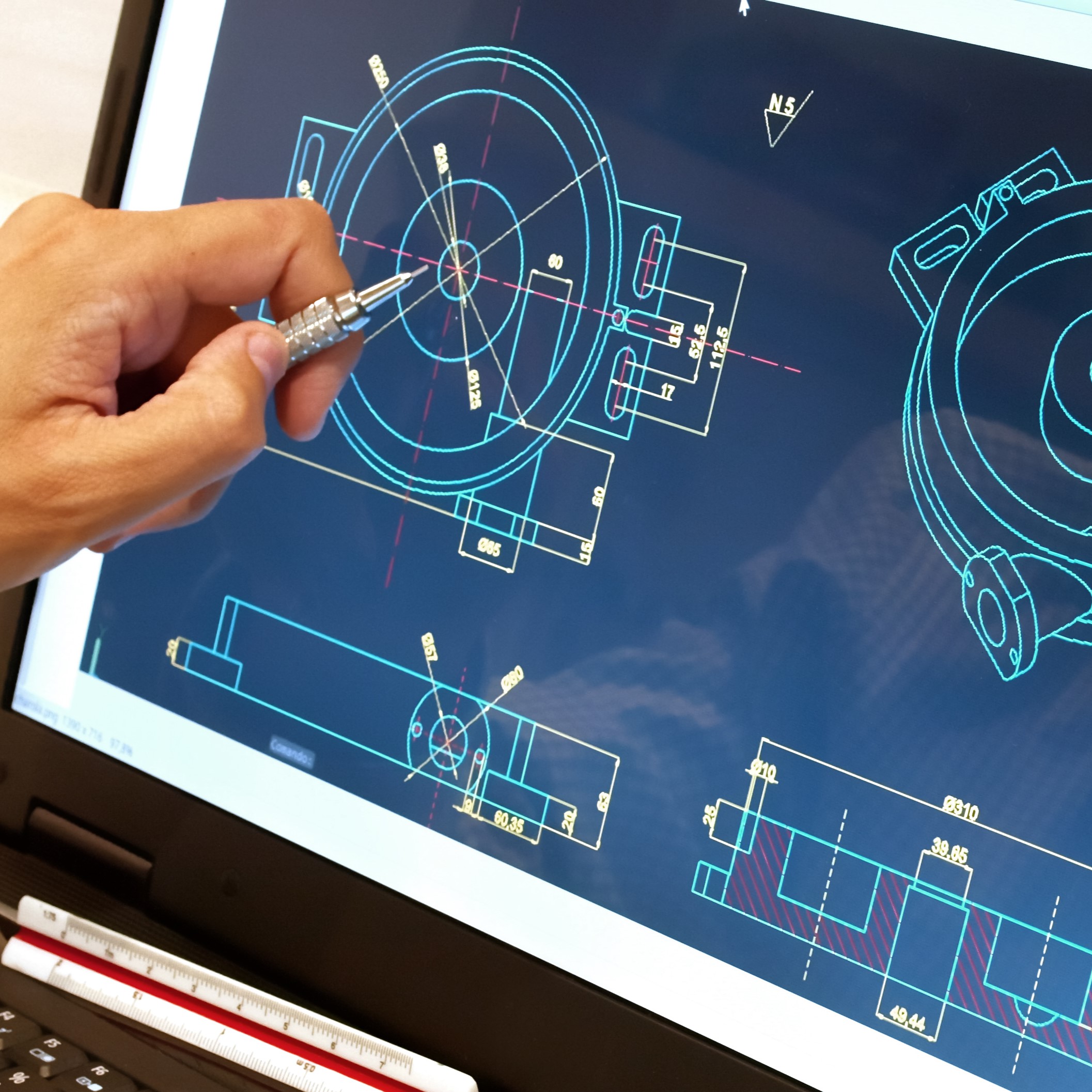

Hazardous Area Panel Design

The design stage is critical in developing hazardous area control panels because it ensures that the final product meets all safety, reliability, and performance standards required for operation in explosive atmospheres. A well-thought-out design addresses potential hazards, complies with ATEX and IECEx regulations, and ensures that all components function correctly under extreme conditions. Proper design minimizes risks, enhances operational efficiency, and extends the lifespan of the control panels, ultimately safeguarding both personnel and equipment.

IECEx Control Systems

Our IECEx control systems are designed for hazardous areas, ensuring compliance with international safety standards. These systems provide reliable and explosion-proof solutions for industries such as oil and gas, chemical, and pharmaceutical, enhancing safety and operational efficiency in explosive environments.

What is Zone 1 and Zone 2?

Zones 1 and 2 refer to areas classified based on the likelihood and duration of the presence of explosive gas atmospheres. These classifications are part of the ATEX directive in Europe and the IECEx system globally.

Zone 1

This zone is an area where an explosive gas atmosphere is likely to occur during normal operation. It is a frequently hazardous area, but the presence of flammable gas is less than 1,000 hours per year.

Zone 2

This zone is an area where an explosive gas atmosphere is not likely to occur during normal operation and, if it occurs, will only persist for a short period. It is less hazardous than Zone 1, with the presence of flammable gas less than 10 hours per year.

Speak to ATEX experts

No matter what your requirement is, our hazardous area experts will be able to assist. We have a vast amount of experience to advise on specification, design and installation. Contact one of our experts today by using the contact form.

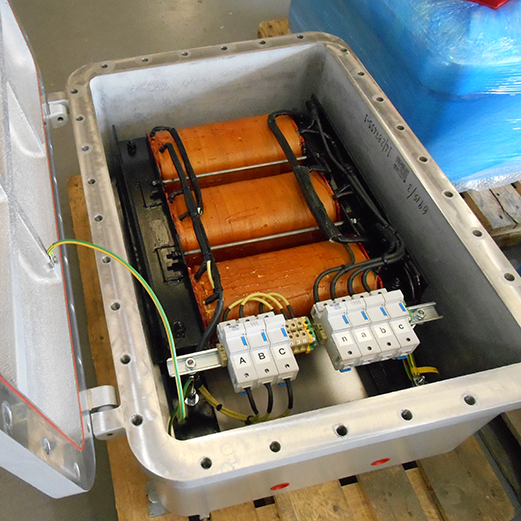

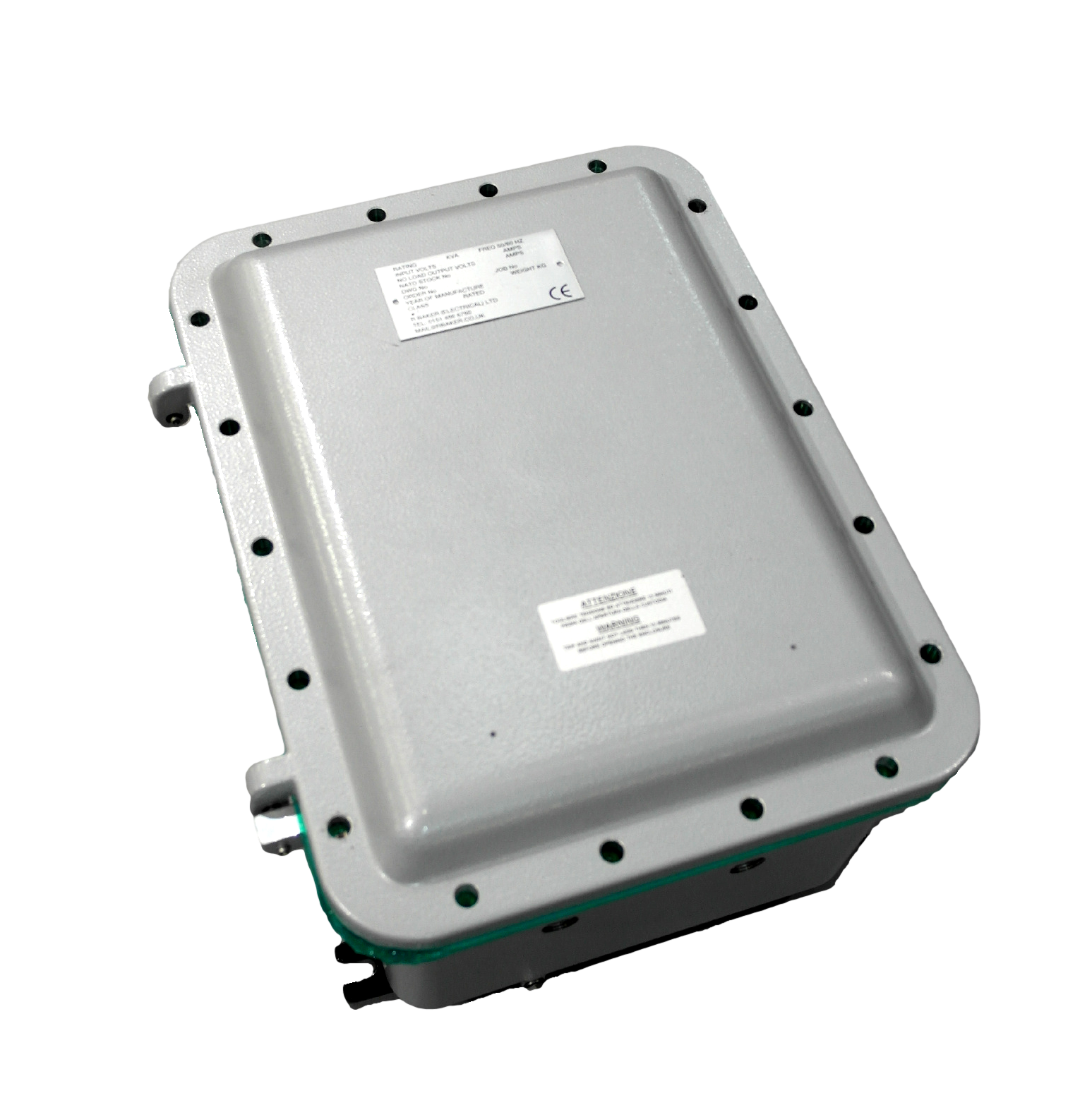

ATEX Control Panels

Our flameproof Exd enclosures solutions come with comprehensive documentation. This includes ATEX, IECEx & GOST approvals. We offer two main enclosures; an explosion-proof aluminium alloy enclosures and an explosion-proof stainless steel enclosure.

For custom designs we can also offer different rates and structural design for enclosures. These enclosures are suitable for those industries where potentially explosive environments exist.

To learn more about our services also click on the links below for our social media feeds.

Contact us on 0151 486 6760

FAQ’s

Here you will find answers for frequently asked questions about Hazardous Area equipment.

What is ATEX (Atmospheres Explosibles)?

This European directive (2014/34/EU) specifies the requirements for equipment and protective systems intended for use in potentially explosive atmospheres. Control panels must be certified to ATEX standards to ensure they do not ignite explosive atmospheres.

What is IECEx?

This international certification scheme provides assurance that equipment and systems are safe for use in explosive atmospheres. IECEx certification is recognized globally and ensures that control panels meet high safety standards.

What is EN Standards?

European Norms (EN) provide detailed guidelines for the construction and testing of equipment used in explosive atmospheres. EN 60079 series, for instance, covers electrical apparatus for explosive gas atmospheres.

What is CE Marking?

In the European Economic Area (EEA), products must bear the CE mark, indicating compliance with health, safety, and environmental protection standards for products sold within the EEA.

Why these standards are important?

Industries such as Oil and Gas, Chemical and Petrochemical, Pharmaceutical, Marine and Offshore, Food and Beverage, and Mining use ATEX and IECEx standards because their operations often involve flammable gases, vapors, dust, and volatile solvents. These standards ensure that hazardous area equipment like control panels are explosion-proof and reliable, preventing accidents and ensuring safety in environments where explosive atmospheres are likely to occur, making them crucial for maintaining operational safety and regulatory compliance.

Accreditations & Memberships